1.Compared with other films such as LLDPE, LDPE, HDPE, PET, PVG, the cost is lower and the output is higher.

2.Higher stiffness than PE film.

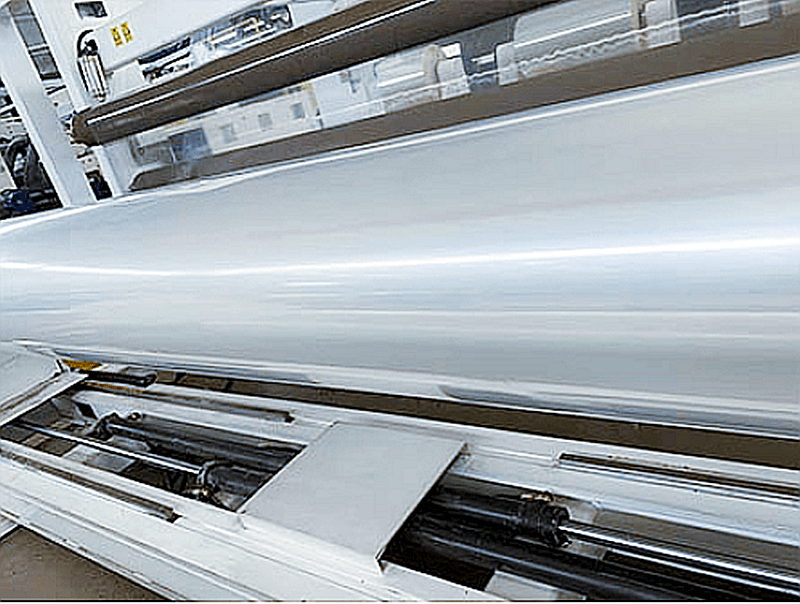

3.Excellent barrier to moisture and odor.

4.Multifunctional, can be used as a composite base film.

5.Can be metalized.

6.As food and commodity packaging and outer packaging, it has excellent demonstrability and can make the product still clearly visible under the packaging.