1.Extrusion production line product introduction:

Polymer self-adhesive film production line, waterproof membrane production equipment, Feiyou self-adhesive plastic film casting line, polymer ethylene propylene waterproof membrane is used to add anti-aging agents, accelerators, and nano materials to make the waterproof membrane’s weather resistance, Heat resistance and low temperature resistance are greatly improved.

PVC, EVA, PE polymer waterproofing membrane production line, it is currently widely used waterproof material inside and outside, suitable for roofing, underground, subway, bridge and high-requirement waterproofing projects. Polymer roofing systems have existed in the North American low-slope roofing market for about 30 years, and many polymer roofing systems, including EPDM roofing systems installed 20 years ago, can still be used normally. Many consumers directly believe that the EPDM waterproof membrane roofing system with reasonable design and proper construction can reach a service life of 25 years or even more than 25 years.

2. Extruder equipment introduction:

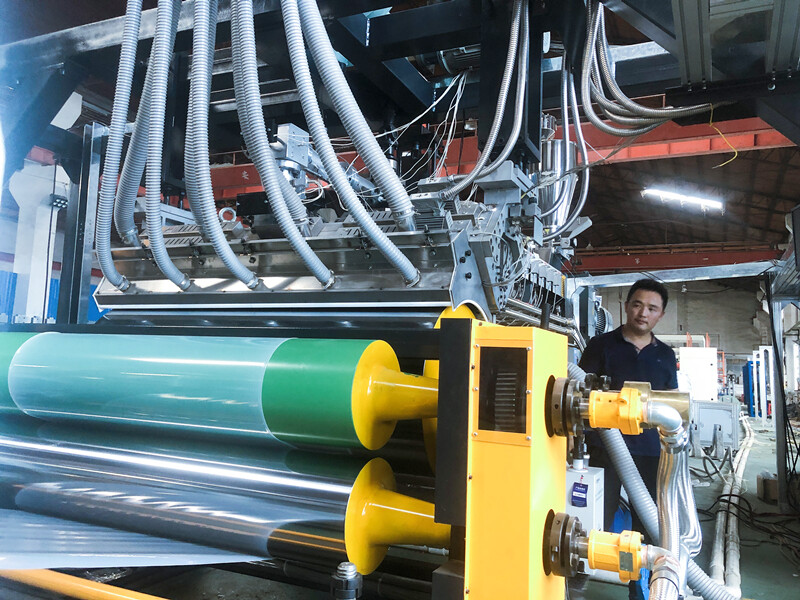

The equipment is mainly composed of extrusion, screen changer, metering pump, mold, six-roll forming, cooling traction bracket, winding and so on. Welcome new and old customers to inquire.

EPDM rubber waterproofing membrane is made of EPDM rubber (high molecular polymer copolymerized by ethylene, propylene and a small amount of dicyclopentadiene), vulcanizing agent, accelerator, etc., made by calendering or extrusion process Polymer coils.

3.Cast film extrusion purpose:

Mainly used for PVC, EVA, PE and other waterproofing membranes, various roof waterproofing products in industry and construction, basements, reservoirs, dams, road tunnels, railway tunnels, air-raid shelters, grain depots, garbage plants, wastewater treatment and other building waterproofing projects .

PE membrane waterproofing membrane, also known as polyethylene membrane waterproofing membrane, has the characteristics of high mechanical strength, aging resistance, strong puncture resistance, high friction coefficient, flexibility, and corrosion resistance.

The company operates HDPE polymer self-adhesive film production equipment, HDPE waterproof membrane production line, polymer waterproof membrane equipment, self-adhesive waterproof membrane extrusion production line, quality assurance, welcome to consult and negotiate.