Leading the 3D Nonwoven Revolution in Uzbekistan

The Challenge

- Market Homogeneity: Local manufacturers in Uzbekistan needed a way to differentiate their products from low-end imports by offering a premium 3D textured top sheet.

- Breathability Demands: Increasing consumer demand for "instant-dry" surfaces required high-precision vacuum perforating.

- Technical Complexity: The need for stable operation under local industrial conditions with easy-to-maintain components.

- High Cost of European Tech: Finding an alternative to European machinery that offers similar 3D depth and hole uniformity without the prohibitive price tag.

Custom 3D & Perforation Solutions for Central Asian Manufacturers

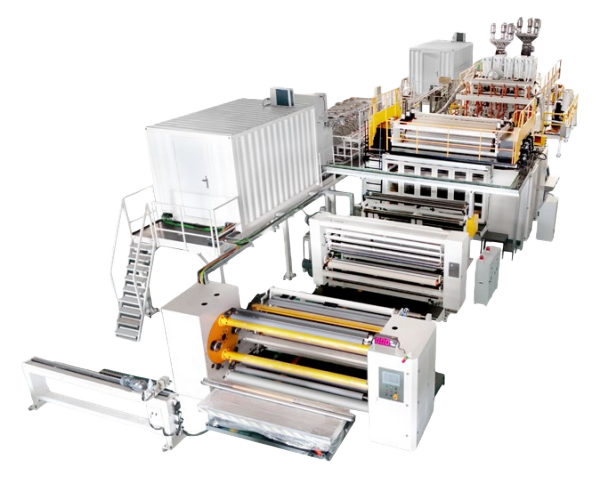

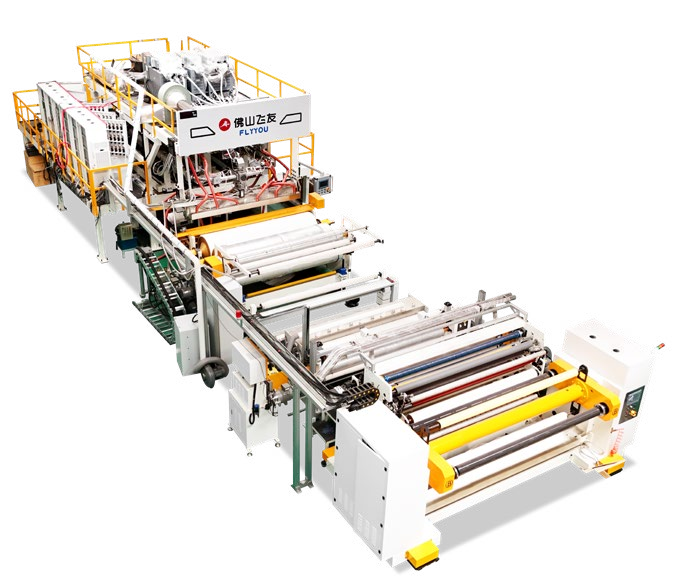

State-of-the-Art 3D Embossing Logic:

We provided laser-engraved rollers that create deep, resilient 3D patterns, giving the nonwoven a "cotton-soft" loftiness highly valued in the Uzbekistan market.High-Speed Perforating:

Integrated a high-frequency suction system that ensures clean, open pores for rapid liquid strike-through, matching A.Celli's performance.FlyYou Brand Synergies:

Leveraging FlyYou machinery's global expertise, we integrated a full-servo drive system that maintains pattern alignment even at speeds of 70m/min.Regional Technical Training:

Futech engineers provided onsite Russian/English language training in Tashkent, ensuring local teams could master pattern changes and tension tuning.The Result

With over 5 units now running in the region, Futech Machinery has helped local brands capture a 35% increase in the "Premium Segment" of the local diaper market."Futech (FlyYou brand) transformed our production. The 3D effect is as good as European machine, but the service and localized support made them the clear winner for our Tashkent facility," noted a leading Uzbek Hygiene Group CEO.