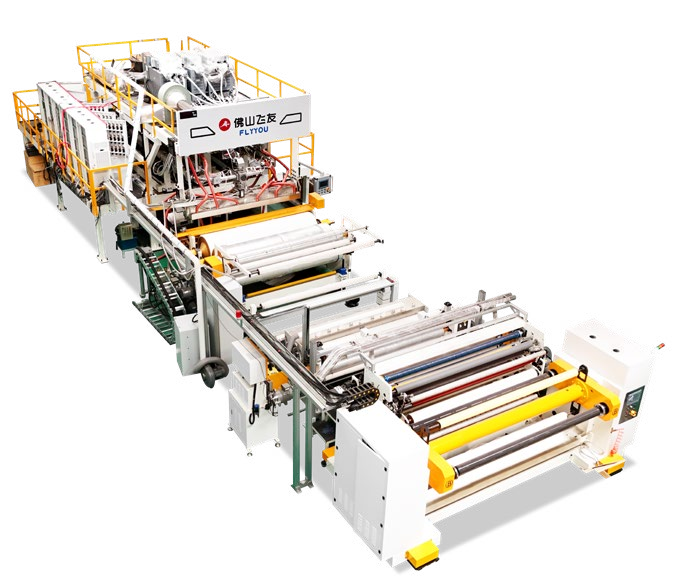

CCM TECH PE Non-Breathable Cast Film Extrusion Line

Industry-Proven Reliability with Taiwan advanced design

- High Quality Output: Specifically optimized to produce high-quality non-breathable PE films used for premium diaper backsheets and sanitary napkins.

- High-Speed Stability (Up to 250m/min): Reinforced frame and precision chill rolls allow for continuous, vibration-free operation at maximum industrial speeds.

- Precision Thickness Control: Integrated online gauging and automatic die-head adjustments ensure a uniform film profile across the entire web width.

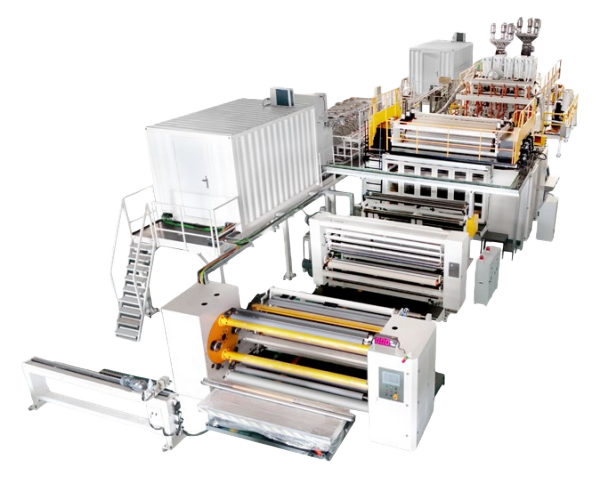

DS TECH PE Non-Breathable Cast Film Extrusion Line

Industrial-Grade Performance Inspired by American Engineering Standards

-

American-Standard Robustness: Built with a heavy-duty frame and high-torque drive systems modeled after the precision logic of DS, ensuring 24/7 vibration-free operation.

-

High-Output Efficiency: Engineered for maximum throughput, capable of stable production speeds up to 200m/min, significantly reducing the unit cost of film.

-

Superior Melt Quality: Advanced screw geometry ensures excellent plasticization and temperature uniformity, even when processing high-viscosity PE resins.

-

Long-Life Durability: Utilizing premium alloy materials and heat treatment processes, our extrusion components offer an extended service life under high-pressure conditions.

Patented PE Non-Breathable Cast Film Extrusion Line (Oil-Temp Extrusion)

Exclusive Patented Technology: Transforming Efficiency with Oil-Temp Extrusion

Advanced Oil-Temp Control: Our exclusive patented technology replaces traditional electric heating with a thermal oil-circulating system, ensuring a temperature deviation of less than ±1°C.

High-Speed Stable Output: While competitors struggle at lower speeds, our oil-temp tech allows for a stable production speed of 200m/min, with a maximum design capacity of 250m/min.

30% Energy Efficiency: The thermal oil system provides more uniform heat distribution and retention, reducing power consumption significantly compared to standard heating methods.

Superior Film Quality: Constant and precise temperature control eliminates thermal degradation, resulting in a more homogenous melt and superior soft-touch film properties.

Inline Printing PE Cast Film Extrusion Line

Efficient One-Step Manufacturing: Integrated Extrusion & Printing

- Cost-Saving In-line Process: Combines film extrusion and 2-color gravure printing in a single pass, eliminating the need for separate printing processes and reducing labor and space requirements.

- Precision 2-Color Gravure Printing: Equipped with a high-accuracy 2-color printing unit, perfect for adding logos, positioning marks, or decorative patterns to diaper backsheets.

- Zero Secondary Contamination: Since the film is printed immediately after extrusion, the risk of dust or static accumulation during storage is minimized, ensuring superior print adhesion.

- Synchronized Speed Control: Advanced tension and speed synchronization between the extrusion die and the printing station ensures no stretching or deformation of the soft-touch PE film.