High-Speed 3D Nonwoven Finishing Success in Russia

The Challenge

High-End Substitution: Russian brands needed to replace European-made materials with locally produced top sheets that offer the same loftiness and dryness.

Complex Material Handling: Stable processing of various nonwovens (Hot-air through, Spunbond) without losing fiber bulkiness.

24/7 Reliability: The need for heavy-duty components that can withstand continuous high-speed production in demanding industrial environments.

Pattern Innovation: A requirement for unique, deep-embossed 3D patterns to help local brands stand out on the shelves of retailers like Magnit or X5 Group.

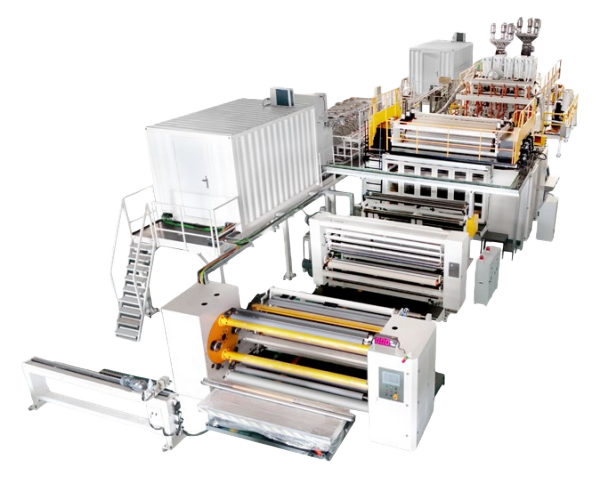

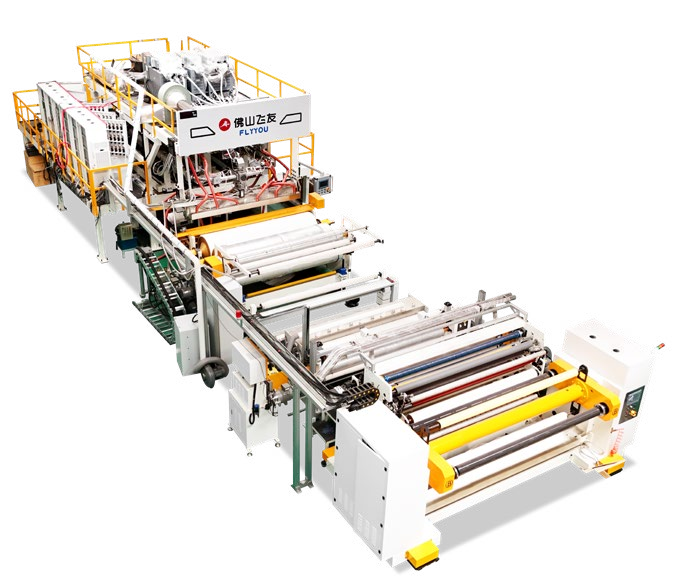

Precision Engineering Tailored for the Russian Hygiene Sector

Premium 3D Texture Technology:

Futech implemented laser-engraved, high-hardness rollers that create deep, permanent 3D shapes. This ensures the "cushion" effect remains after packaging, rivaling the quality.

Advanced Vacuum Perforation:

Our high-speed airflow system creates uniform, burr-free pores. This technology provides the rapid liquid strike-through performance that European machine users expect.

Heavy-Duty Build:

Utilizing the robust mechanical, the line features a reinforced steel frame and high-precision heating systems to ensure zero thermal deformation.

Localized Remote & Onsite Support: We offer comprehensive Russian-language documentation and remote diagnostic capabilities to ensure uninterrupted production.

The Result

Our Russian clients have reported a 20% increase in sales of their premium diaper lines after switching to Futech's 3D embossed top sheets."Futech Machinery (FlyYou brand) has given us the technical edge we needed. Their 3D embossing depth and hole consistency are on par with Pantex, making them our primary partner for future expansions," said a key manufacturer in the Moscow region.