Driving Medical Textile Localization in Saudi Arabia

The Challenge

- Stringent Medical Standards: The Saudi Ministry of Health requires zero solvent residue and high peel strength for all surgical textiles.

- Harsh Operating Environments: Machines must maintain consistent glue viscosity and mechanical precision despite the region’s extreme ambient temperatures.

- Material Sensitivity: Bonding ultra-lightweight PE films (12-18 GSM) without heat deformation or wrinkling.

- Dependency on Imports: A strategic need to reduce reliance on European-laminated fabrics by establishing high-end domestic production.

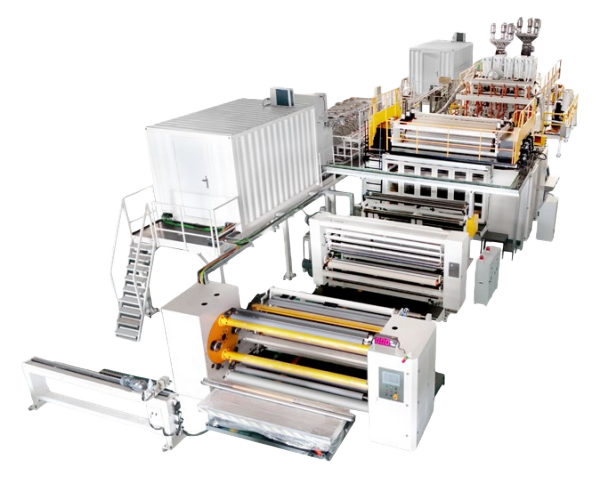

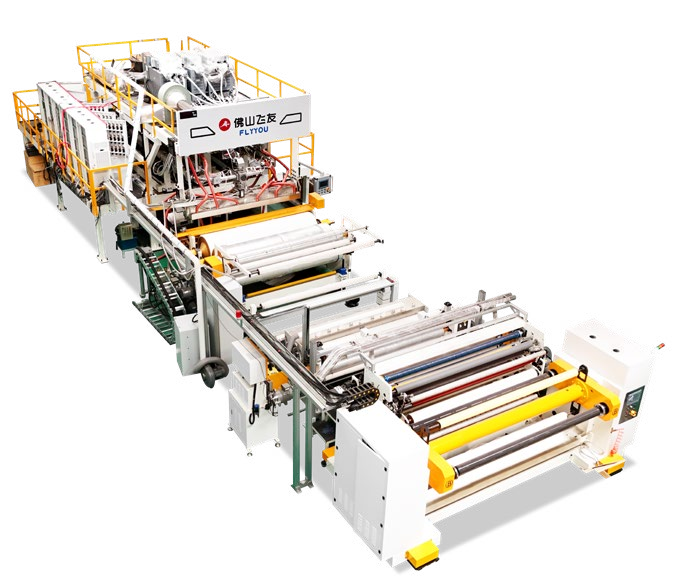

Precision Lamination Engineered for the Middle East

Medical-Grade Slot Die Technology:

Futech(under FlyYou brand) utilizes precision coating heads that rival NDC and Nordson in terms of GSM uniformity, ensuring every square inch of the medical drape is safely bonded.

Advanced Heat Management:

Leveraging Futech machinery's(under FlyYou brand) expertise in thermal control, we integrated a specialized cooling system to protect thin PE films during the hot-melt process.

Zero-Solvent PUR Bonding:

Our 100% solid PUR reactive system ensures the finished laminate is eco-friendly, breathable, and capable of withstanding sterilization—essential for the Saudi healthcare sector.

Remote Intelligent Support:

24/7 Cloud-based diagnostics to support Saudi factory teams, ensuring minimal downtime in high-stakes production environments.

The Result

Our Saudi clients have successfully replaced 60% of their imported medical fabrics with self-produced laminates, significantly improving their profit margins."Futech (FlyYou brand) gave us the technical confidence to compete with European suppliers. Their PUR lamination precision is as reliable as Nordson, making them a vital partner for our Vision 2030 goals," remarked a leading medical factory owner in Riyadh.