Customer Background:

A large medical hygiene group in Brazil, mainly engaged in protective clothing, surgical gowns and other products, whose products are exported to South America and North America. It has extremely high requirements for the production capacity and stability of PE base films. The previously used equipment had insufficient production capacity and could not stably produce low-GSM breathable base films below 20g/㎡, which restricted the R&D of high-end products.

Equipment Application Solution:

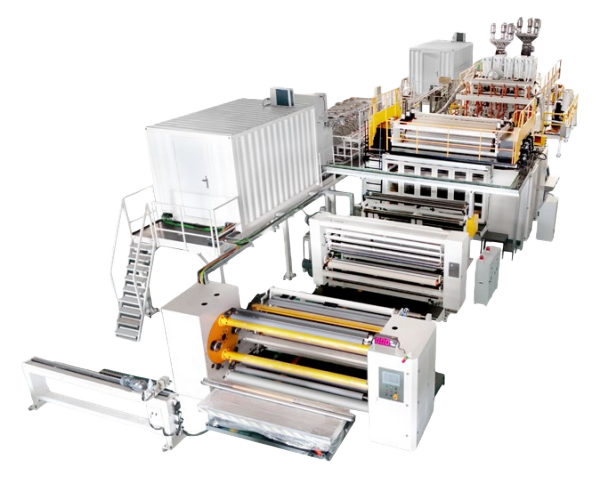

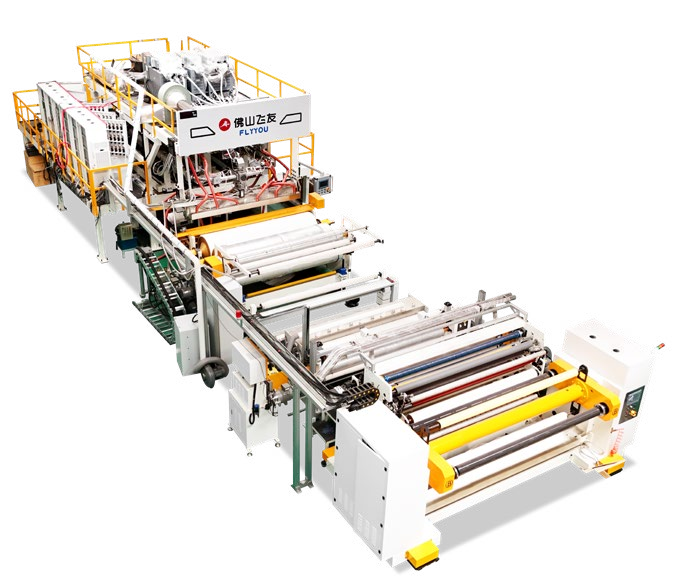

Empowering Brazilian Hygiene Market: FlyYou Integrated Cast Film Line Success Story

Project Background: Meeting Diverse Market Demands in Brazil

The Challenge: High Flexibility Without Compromising Quality

Space Optimization: The factory required a compact yet powerful footprint.

Rapid Switching: The ability to switch between breathable (MDO active) and non-breathable (MDO bypass) modes with minimal downtime.

Precision Control: Maintaining the same GSM uniformity and soft-touch properties found in Midian (Korea) or Wellson equipment.

Localized Support: Reliable technical service and formula guidance within the Latin American time zone.

The FlyYou Solution: A Specialized Integrated Cast Film Extrusion Line

Universal Extrusion with Patented Oil-Temp Tech:

FlyYou Machinery provided our patented oil-temperature control system, ensuring stable extrusion for both pure PE and high-CaCO3 blends.Bypass-Enabled MDO Unit:

We engineered a reinforced MDO stretching unit that can be precision-tuned for breathability or bypassed for soft-touch non-breathable film production.One-Touch Mode Switching:

Integrated Siemens TIA Portal allows the Brazilian operator to switch production recipes in minutes, rivaling the automation.Results: 30% Increase in Production Efficiency

Since the installation in Sao Paulo, the client has reported a 30% increase in overall equipment effectiveness (OEE). By using one FlyYou machinery line to cover their entire product range, they saved significantly on energy and labor costs."FlyYou provided us with the flexibility of a Euro machine but with a much faster ROI. The integrated design is a game-changer for the Brazilian market," commented the Client's Technical Director.