High-Speed Slitter Success Story: Advanced Film Converting in Turkey

The Challenge

- High-Volume Demand: The client needed to process massive quantities of breathable film from their cast lines without creating a bottleneck.

- Material Sensitivity: Slitting ultra-thin (10-15 GSM) breathable film requires delicate tension to prevent over-stretching, a common issue with standard slitters.

- Labor Efficiency: The client sought to reduce manual labor and improve safety during the unloading of heavy finished rolls.

- Export Standards: The finished rolls had to meet strict European quality standards for diaper and medical gown production.

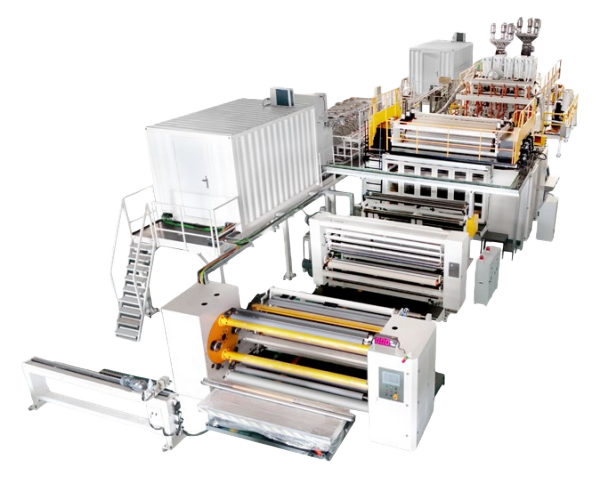

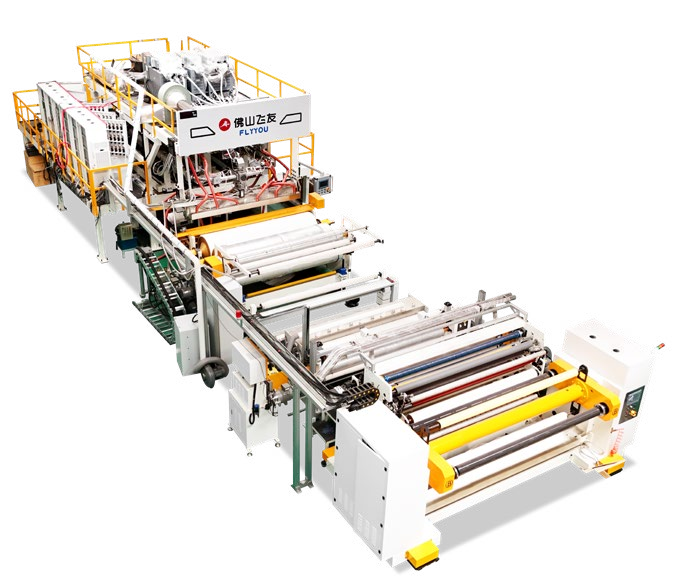

Custom-Engineered Excellence for Turkish Converters

600m/min High-Speed Precision:

We provided a heavy-duty frame design that eliminates vibration, ensuring the stability.

Automatic Discharge & Handling:

Futech Machinery (under our FlyYou brand) integrated a fully automatic unloading tree and conveyor system, reducing roll changeover time by 50% and minimizing operator fatigue.

Advanced Differential Air Shafts:

Essential for Turkey's diverse material range, these shafts ensure perfect winding tension even when film thickness varies across the web.

Smart Web Control System:

A high-response digital guiding system ensures the edge alignment precision required for high-end European export markets.

The Result

The installation has allowed the client to increase their daily slitting capacity by 40%. The automatic features have significantly improved factory safety and efficiency.

"Futech Machinery(under our FlyYou brand) provided us with an European slitter at a much more competitive investment point. Their automatic discharge system is flawlessly designed for our high-capacity needs in Gaziantep," stated the Production Manager.