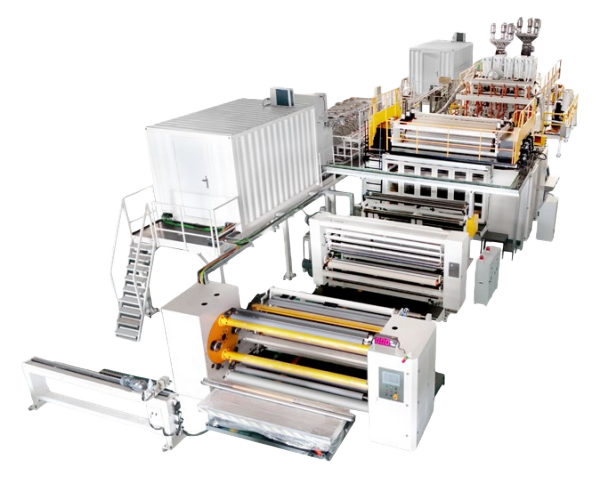

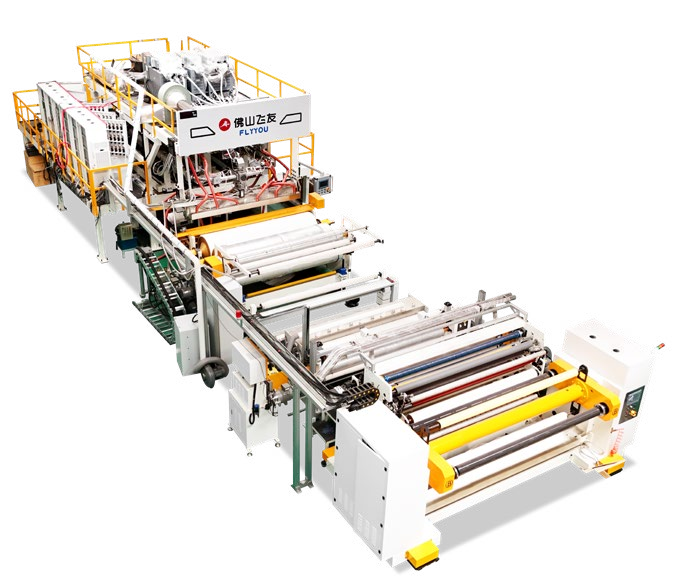

Pakistan Success Story: High-Speed PE Breathable Film Line Commissioning

The Challenge

High Ambient Temperatures: The client needed a machine that could maintain consistent melt temperatures despite Pakistan's intense summer heat.

Cost of Import: Traditional European or Korean machines carried prohibitive costs and long lead times.

Skill Gap: The need for a user-friendly interface and comprehensive onsite training for local operators.

Uniformity: Achieving a stable MVTR (Moisture Vapor Transmission Rate) for high-end export-quality backsheets.

Custom-Engineered Solutions by FlyYou Machinery

Patented Oil-Temp Extrusion System:

Unlike basic electric heating found in other traditional machine, our patented oil-cooling/heating screw ensures the melt remains stable even when factory temperatures exceed 40°C.Precision MDO Stretching Unit:

We integrated a heavy-duty MDO unit with the same precision logic, ensuring perfect micropore formation for 12-15 GSM films.Localized Training & Formula Support:

FlyYou engineers stayed onsite in Pakistan for 3 weeks, providing full formula guidance (PE+CaCO3 ratios) to ensure the client achieved 280m/min stable output.The Result

The factory now produces over 15 tons of high-quality breathable film daily, supplying major diaper brands in Karachi and Lahore. The client has significantly reduced their reliance on imported raw materials."FlyYou Machinery provided us with a world-class line at a fraction of the cost. Their patented oil-temp system is essential for our climate," stated the Project Manager.