Top Sheet Perforated PE Film Machine

Cutting-Edge Perforating Features by FlyYou

-

Advanced Vacuum Suction Roller: A high-precision micro-perforated drum designed for various patterns (hexagonal, circular, etc.), ensuring 100% perforation rate.

-

Intelligent Siemens Control System: A fully integrated TIA Portal interface for synchronized control of extrusion, vacuum, and winding, similar to high-end Jingwei technology setups.

-

Uniform Melt Distribution: Optimized T-Die and screw geometry ensure the PE film maintains perfect GSM uniformity before the perforating stage.

-

Anti-Static Treatment Unit: Built-in high-power static eliminator ensures the perforated film remains easy to handle for downstream converting machines.

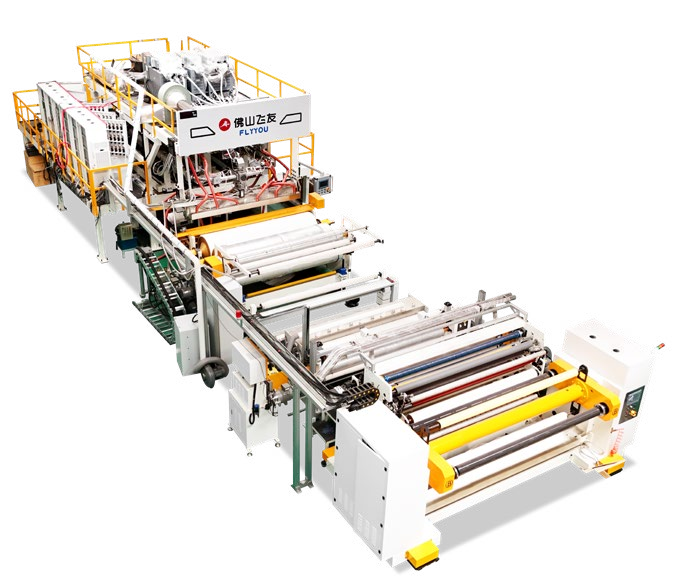

PUR Hot Melt Adhesive Coating Laminating Machine

Why futech machinery is the Leading Choice for Medical Lamination?

-

Medical-Grade Precision: Engineered to meet the stringent requirements of medical textiles, ensuring a flawless bond between PE film and nonwoven, comparable to NDC coating accuracy.

-

Breathability Preservation: Our advanced PUR application ensures the finished laminate retains its essential breathability and soft touch, a benchmark often associated with HHL (henghuilong) technology.

-

High-Speed Productivity: Achieve stable production speeds of 150-200m/min, offering a robust and cost-effective alternative to MEK laminating lines.

-

Eco-Friendly Bonding: 100% solvent-free PUR hot melt process, ensuring zero chemical residue, which is vital for surgical gowns, drapes, and underpads.

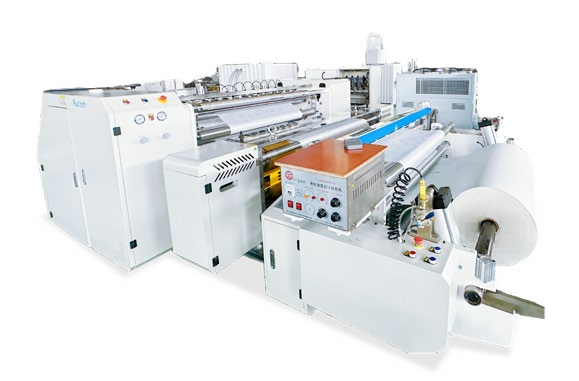

High-Speed Slitter Machine

Technical Features of High-Performance Slitters

- Ultra-High Speed Output: Engineered for stable operation at speeds up to 600m/min, significantly boosting productivity.

- Precision Tension Management: Utilizing a state-of-the-art web control system to ensure consistent tension for even the most delicate materials like 10 GSM breathable PE film.

- Superior Edge Quality: Precision knife-cutting technology delivers smooth, burr-free edges, meeting the high standards.

- Minimized Downtime: Fully automatic loading and unloading features reduce changeover time, offering a faster ROI for large-scale converters.

High-Speed Rewinding Machine

Technical Features of our High-Performance Rewinders

- Automatic Edge Guiding System: High-response EPC/LPC system ensures perfectly aligned edges, rivaling the accuracy of international web-control standards.

- Surface and Center Rewinding: Versatile winding modes to handle various material types, from thin hygiene films to heavy-duty nonwovens.

- Pneumatic Knife System: Optional in-line slitting feature for trimming edges during the rewinding process, providing a "2-in-1" efficiency.

- Intuitive HMI Interface: Full Siemens PLC control with a user-friendly touchscreen, allowing for rapid recipe changes and real-time tension monitoring.

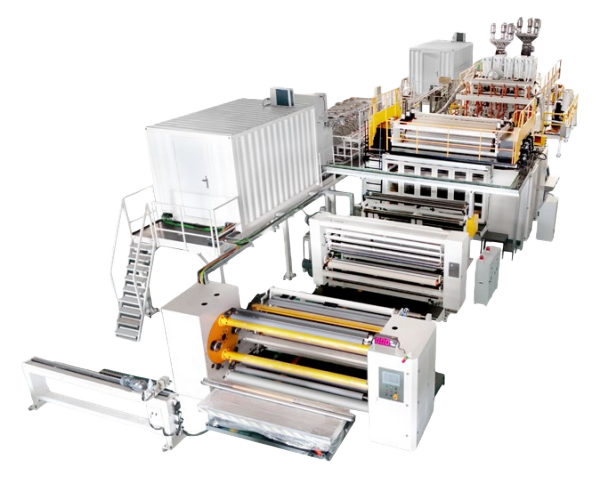

Nonwoven 3D Embossing & Perforating Machine

Elevate Hygiene Comfort with 3D Embossed Technology

- Premium 3D Visual & Tactile Effect: Produces high-loft, deep-embossed patterns that enhance the "cloth-like" softness and premium look of sanitary products.

- Superior Dryness & Breathability: Integrated high-speed perforating creates clean, burr-free pores for rapid fluid acquisition.

- No Loss of Bulkiness: Specialized heat-setting and vacuum technology ensure the 3D structure remains resilient even under packaging pressure

- Cost-Efficient High-End Solution: Achieve European-level texture and perforation quality with the localized service and superior ROI provided.

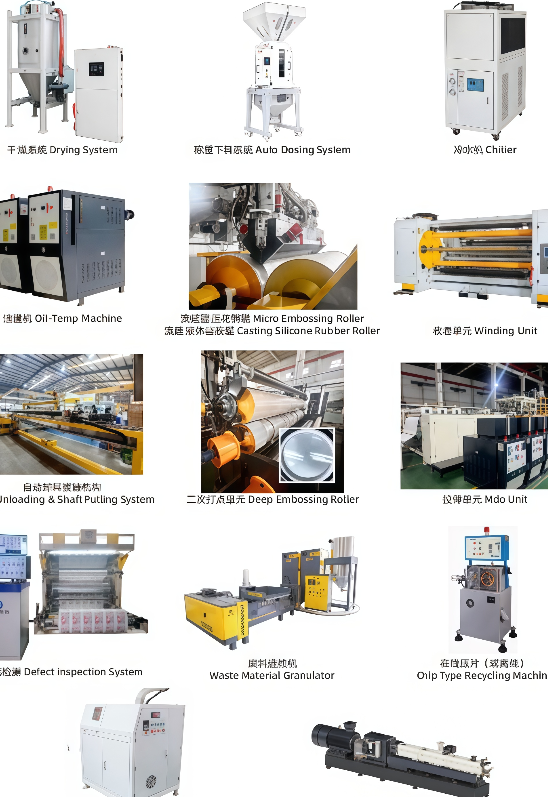

Supporting Units for Breathable & Non-Breathable PE Cast Film Extruder

●Full set supporting units for PE cast film extruder: drying, auto dosing, MDO, recycling. ISO certified, ideal for breathable/non-breathable film production.